Kisumu Waste Strategies & Waste reports

Complete set of Kisumu County Strategies & other Waste reports have been reviewed indicating MSW characteristics and Energy potential.

To understand the Gasification plant please click on arrow icon above for an example in Japan

UK Facilitation company PSECC Ltd

The UK company responsible for facilitating this project is PSECC Ltd working with SyScraft Ltd in Nairobi – Waste-to-Wealth to build an Integrated Waste Management Facility 20 km away from CBD in Ombeyi Ward, Muhoroni Sub-County. Click on above boxes icon to see also another Gasification Technology plant from the UK company EQTEC that serves as example.

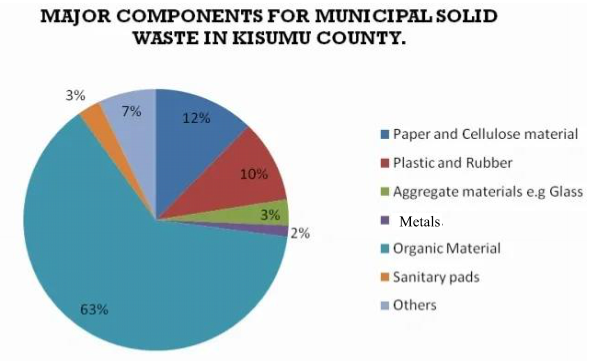

Our focus is on the Inorganic fractions of the MSW and with the new trucks then collection rates will increase bringing the MSW available upto 600 tpd. We can also process tyres and some medical waste to increase calorific value for energy production.

Syscraft Ltd

Our Kenya in Country partners – facilitation and project management, backed up by Headway USA, PSECC Ltd, and Sarralle. Click on icon above for PSECC Ltd website

Our two year development programme with Kisumu – we aim for Waste-to-Wealth.

We will produce building products and renewable electricity, recycled glass, metals and ash and some plastics and liquid fuels in the second and third phases of this project together with Fertilizers and cooking gas.

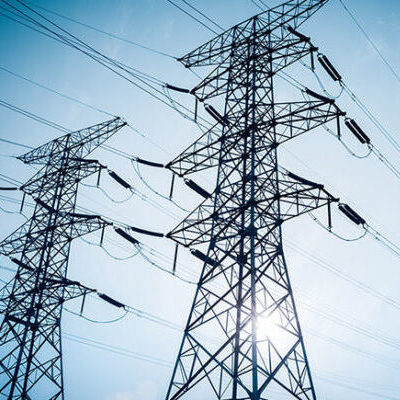

One of our project partner companies Turmec have diverted 44.435 million tons of MSW from going to Landfill dumps and now being processed

In terms of economic inputs by the County (and subsequent customer for the electricity – we are proposing the Power Purchase Agreement cost per KWh be set at 12.5 Kenyan Shillings or $0.10 USD) – Once agreement has been reached to appoint us and sign off on our funding agreements then a focused Feasibility study should find that an injection of payment from the budget for the electricity will be needed only in the early years, after which the energy boost to the local industries and living standard should raise the floor on County revenues, such that the annual cost is easily afforded so the cost of any Power Purchase Agreement (PPA) become much less of a burden on the County as growth occurs – the Circular Economy in action. If the energy payment collections for delivered energy is smart, the Kisumu County Government should have almost no budgetary outlays, and can simply pay from those new energy revenues, which in turn should attract new industries to base in Kisumu, increasing their standard corporate revenues as well as energy revenues.

Structure of Waste Management in Kisumu

Each Waste plant will be incorporated into an Educational Centre Net Zero

Waste-to-Wealth. PSECC Ltd’s partners, Syscraft Ltd, Headway USA, Sarralle & Nemchem offers this proposal to construct the Kisumu County Environmental Education Centre with a Total Recovery Facility® (“TRF®”) inside, which will produce building products and renewable electricity, recycled glass, metals and ash and some plastics and liquid fuels in the second and third phases of this project together with Fertilizers and cooking gas.

Environmental Education Centre that will convert MSW and other waste streams into composite building products and clean electricity and renewable on-road transportation fuels (the “Project”), fertilizers and cooking gas.

The system proposed will initially consume up to 600 tpd in the plant for the City of Kisumu, the County has 5,720 tons of MSW currently available in the Kisumu County area, so nine plants can be built over the next five years.

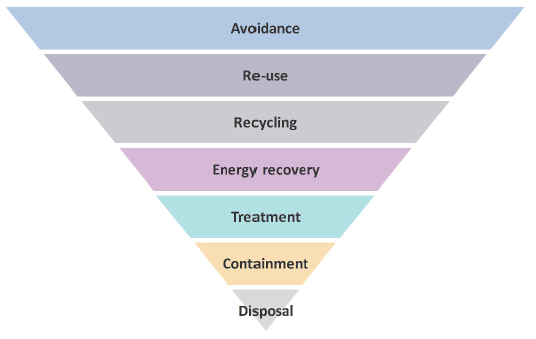

This will eliminate the current practice of landfill dumps saving millions of dollars over current practices. The Project will be scalable to take advantage of future growth opportunities expandable to all the MSW in the including agricultural waste and other various waste streams giving Kisumu 100% reuse and complete recycling with no need for any waste to go to a landfill.

About Kisumu waste

Energy for Net Zero

The City’s Solid Waste Management Crisis Kisumu city is faced with problems of lack of solid waste collection facilities and low efficiencies in operation of existing facilities as well as the design, capacity and location of final disposal sites. The poor management of solid waste has resulted into generation of leachate which pollutes the ground water and soil, the spread of infectious diseases, blockage of sewers and drainage systems, spread of foul smoke from private burning of waste as well as pollution of Lake Victoria through run-off. Plastic waste used in most packaging is the most conspicuous nuisance, littering many parts of the City‟s commercial, industrial and residential neighbourhoods. Furthermore, scavengers and others are exposed to health risks as no separation of hazardous waste fractions is practiced. As stated above, most of the solid waste generated in the city remains uncollected with a collection efficiency estimated at 30%. The collection that takes place is shared between the city authority and a few private collectors mainly concentrated in the high income areas, leaving the poor peri-urban neighbourhoods largely unattended. Waste transported to the dumpsite for disposal is not properly managed, often applying open burning to reduce the waste volume. Many households, particularly in the peri-urban and extended areas do not have the privilege of any mode of collection, and have resorted to private burning of waste or digging their own pits to bury the waste on site.

Horizon 2030

Kisumu Integrated Solid Waste Management Plan (KISWaMP)

County Government of Kisumu City of Kisumu Kisumu Integrated Solid Waste Management Plan (KISWaMP) by horizon 2030 An updated, revised and operational version of the previous plan

Kisumu City generastes 600 tpd MSW – Kisumu Countyn generates 5,720 tpd MSW

Kisumu County Government Data

Kisumu City 600 tonnes per day of MSW is generated our Gasification & Recycling could produce 671.54 KWh per tonne of MSW = 112,482 MWh of electricity each year from the plant.

Kisumu County generates about 5,720 tons of solid waste per day (as per Kisumu-County-CIDP-II-2018-2022-3) ten further plants possible.

Our focus is on the Inorganic fraction and the organics can be sold onto another processor.

Clear Landfill sites, reduce waste.

Kisumu transition into a Circular Economy – Zero Waste – Zero Landfill

Kachok Landfill Site

The Kachok Landfill site in Kisumu – the new plant will be sited in Kisumu and use the waste in the landfill as a mix with normal generated daily waste. Pickers can also be paid to bring plastic & tryes to our plants.

Waste Hierarchy

Kisumu City 600 tonnes per day – we recovery energy by treating the waste with Gasification and 100% Recycling of glass, metals and Ash, which are then reused for manufacturing of new goods. No contamination of by-products – Circular Economy. ZERO waste is disposed to landfill

The need for Sustainable Waste Management

Officials wished to see improvements in waste management in Kisumu and are very pleased to have the funding and Gasification & Recycling plants from PSECC Ltd – Renewable Electricity produced, 100% recycling of glass and metals. New Concrete Building blocks made from Ash & Glass mixed with cement

The need – the solution

Kisumu have their strategy & we have the solution & funding

Kisumu have their Strategy to reduce waste and have a new Waste Management Facility just opened to try to be more sustainable

.

Sarralle or Siemens EPC company to build plants

We do have another company – Alset Power Gasification and they appoint Siemens to build their plant. Siemens have built over 1,000 Power Plants Globally. Other technologies are available from Sarralle.

Our Gasification & Sarralle EPC company to build the plant

A full funding package for the Recycling & Gasification plant (s)

Continual monitoring

Power producers, grid operators, power utilities, industrial companies, and municipalities can manage tasks economically and efficiently

Generation & installations teams

The most professional installation teams work on this project guaranteeing maximum power output, efficient waste handling and monitoring emissions.

Recycling, Energy production Gasification and Manufacturing

100%. Recycling of the glass, metals, ceramics & ash and manufacture of building blocks and food production using waste carbon dioxide. Plastic is used for electricity production

Glass is recycled

What comes out – Zero waste goes to the landfill sites from our plant as new products are made from the 15 tonnes per day of glass from the plant, ash & ceramicsCircular Economy in action

Metal is recycled

ZERO waste goes back into the landfill sites – 10 tonnes per day from the plant of metals are resold for reuse in manufacture of new products .

New building blocks for homes

New products are made such as building concrete blocks for house building or road building material from the 15 tonnes per day (tpd) of glass & 10 tpd of Ash 100% Reuse & Recycling

Tyres processed & Renewable Energy produced

Adaptive planning, Circular Economy, manufacturing & food production

Tyres are Recycled

Rubber is used for electricity production the steel is recycled for new products 100% Reuse & Recycling

Electricity Generated

Renewable Energy – 112,482 MWh each year of electricity is produced now in Kisumu from the cleanest method possible, Gasification with Zero to Landfill

Food production

Our partner company PSECC Ltd are currently the Lead company on an International Collaboration Agricultural project in Kenya to cool gooseberries by solar window to be funded in 2022 by the UK Government InnovateUK. Our partners are the University of Greenwich & Moi University in Kesses, Eldoret, Kenya & Maridadi Farm Enterprise, Shamberere Hse. Moi Avenue, Kitale, Kenya. Also – PSECC Ltd can build greenhouses to grow fresh produce for the local markets. The Tomato plants absorb the CO2 and convert it to oxygen, thus making the Zero-Waste power plants 100% earth-friendly and environmentally qualifies for carbon credits internationally.

Structure of waste management in Kisumu – 30% of waste is collected each day, the majority of waste is Landfilled